Plasma-Punch Machine Services

ES Denver offers steel projects as part of its scope of services. ES Denver uses a large format CNC plasma machine to cut steel. The bed can accommodate steel up to 8' x 16'. With the punch, the holes will be perfectly round and in the correct place.

In manufacturing and construction, a plasma cutting table is an efficient and versatile tool for cutting heavyweight and thick materials. The machine is controlled by a computer and helps to get an accurate cut. We save both time and money using the machine. Having the ability to cut up to 200 inches per minute, this machine is efficient. We can ensure that material sheets are used efficiently and that unnecessary material waste is avoided.

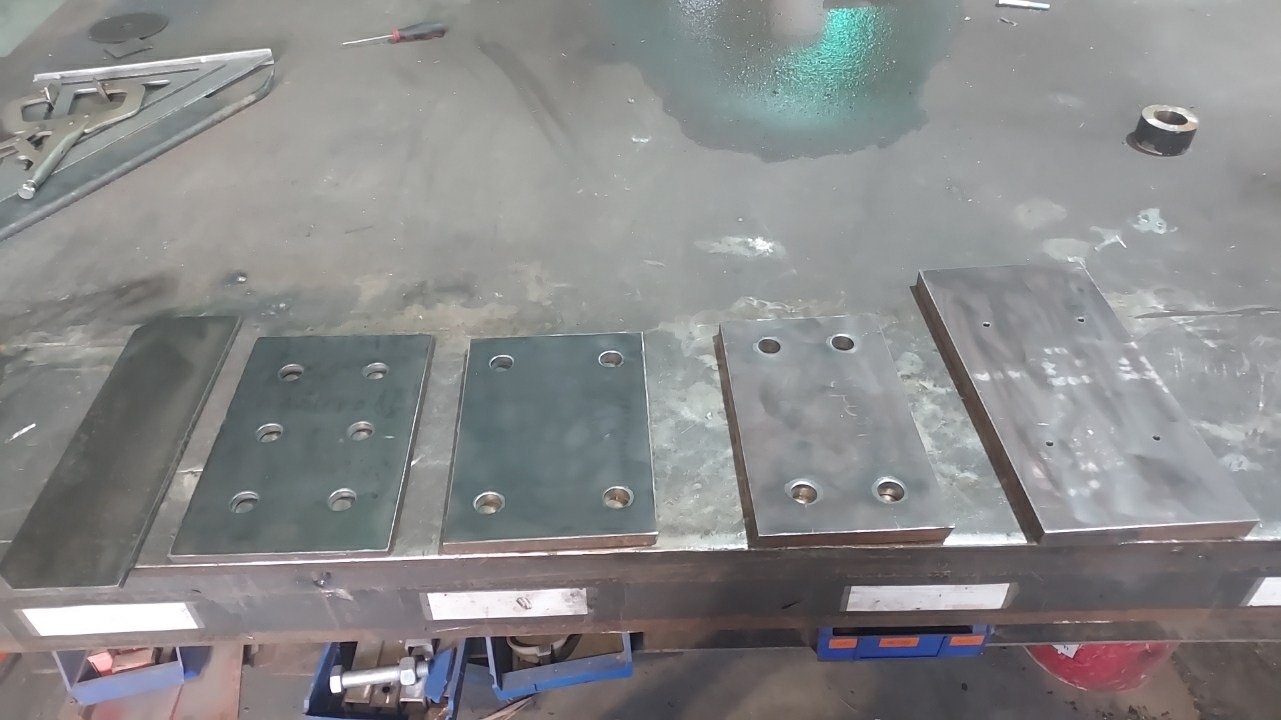

Plates that have been cut by our plasma table

Pizza Nozzle for Emirates Airlines

Engineering Studio Denver (ESD) was visited at their office by Emirates Airlines who explained their need for a re-designed "pizza nozzle." Read more about how we redesigned the prototype.

Engineering Studio Denver (ESD) was visited at their office by a potential client who explained his need for a re-designed "pizza nozzle," the prototype of which he brought with him. This prototype, shown in the photo below, was machined from a solid piece of food-grade plastic.

It was being tested by Emirates Airlines at their food processing facility, presumably to extrude strips of pizza dough onto a conveyor belt prior to cooking. Tests showed that the opening in the nozzle was too wide.

ESD was contracted by this client to make a drawing of the re-designed nozzle for use in a 3D printer to make the nozzle.

The opening in the prototype nozzle was 0.09 inches x 5 inches. The opening in the redesigned nozzle is 0.09 inches x 3 inches, and the width of the body was changed accordingly to save plastic. The drawing of the re-designed nozzle is shown below.

ESD was loaned the original nozzle by their client. No drawings were provided. All the dimensions of the nozzle were to be measured and recorded. The shape of the nozzle made measuring it in order to create a fabrication drawing quite a challenge. Determining the size and specification of the threads on the nozzle proved to be the most difficult aspect of this project. The recorded dimensions were used to make the drawing of the re-designed nozzle, completed in approximately 5 hours, start to finish.

ESD contacted a 3D printing company, emailed them the drawing, and had the nozzle made from food-grade plastic. The new nozzle was retrieved from the 3D printing company by ESD's client.

ESD provided their client with the drawing of the re-designed nozzle and the specifications of the food-grade plastic used to print the nozzle.